Best 3D Printers for Automotive Parts

Creating automotive parts with 3D printers is a cost-effective and highly efficient method for prototyping and production. Whether you’re crafting brackets, engine components, or interior trims, a suitable 3D printer ensures precision and durability. Below, we highlight best 3D printers for Automotive parts, their features, and a detailed comparison table to help you make the best choice.

Comparison Table

Below is comparison chart for best 3D Printers for Automotive parts

| Scanner | Printing Technology | Ease of Use | Build Volume | Precision | Material Supported | Best For | |

|---|---|---|---|---|---|---|---|

|

Prusa i3 MK3S 3D Printer | FDM | Remote monitoring, touchscreen interface | 9.84×8.3×8.3 inches | ±0.01 mm | PLA, ABS, Nylon, Carbon Fiber | Check Price |

|

QIDI Q1 Pro 3D Printer | FDM | Wi-Fi connectivity, user-friendly touchscreen | 9.65×9.65×9.45 inches | ±0.05 mm | PLA, ABS, ASA, PETG, TPU, PA, PC, Carbon Fiber, Glass Fiber | Check Price |

|

ANYCUBIC Photon Mono X 6Ks | Resin | Simple resin setup | 7.7 x 4.8 x 7.8 inches | High 6K | Standard, ABS-like, Flexible Resin | Check Price |

|

FLASHFORGE Adventurer 5M Pro | FDM | Cloud-based printing, auto-bed leveling | 8.66 x 8.66 x 8.66 inches | ±0.1 mm | Batch printing | Check Price |

|

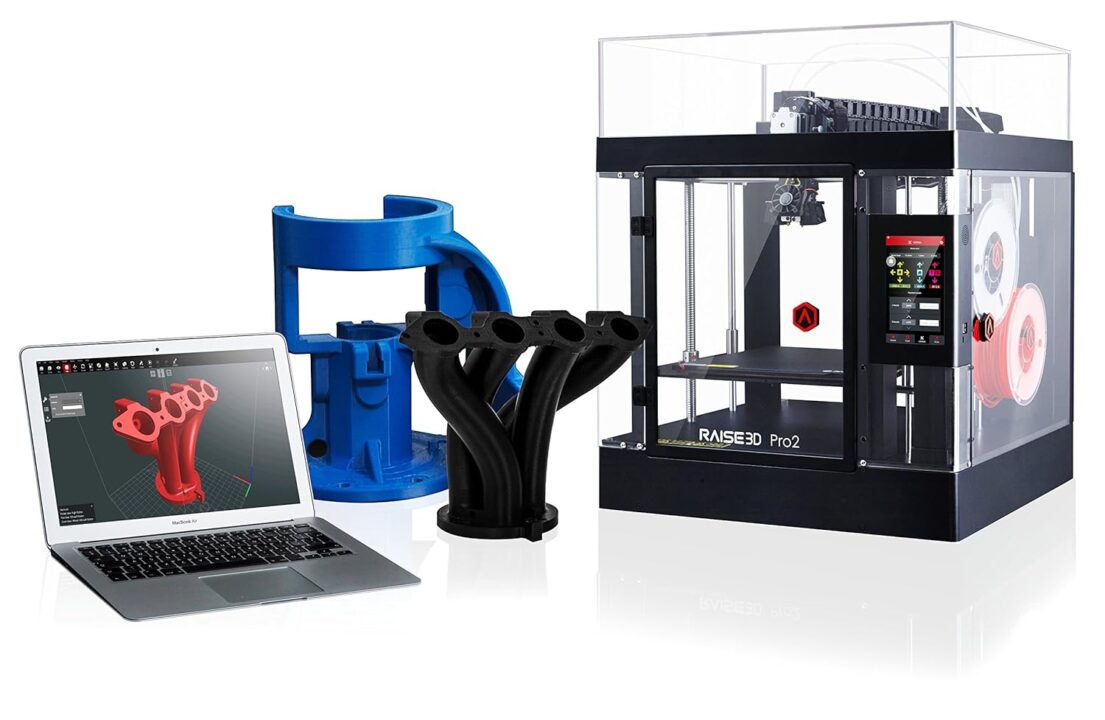

Raise Pro2 3D Printer | FDM | Remote monitoring, touchscreen interface | 12 x 12 x 11. 8 inches | ±0.01 mm | PLA, ABS, PC, Carbon Fiber | Check Price |

Top 3 Picks for Best 3D Printers for Automotive Parts

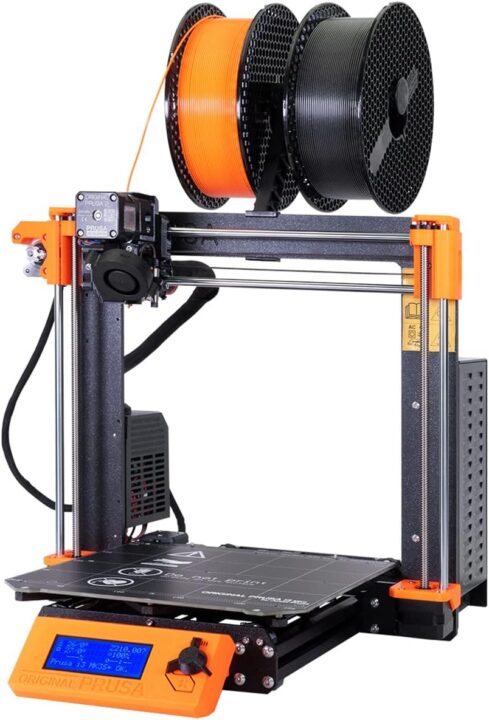

1. Prusa i3 MK3S 3D Printer

“Best 3D Printers for Automotive Parts“

Key Features

-

Build Volume: 9.84×8.3×8.3 inches

-

Material Compatibility: PLA, ABS, Nylon, Carbon Fiber

-

Precision: ±0.01 mm

-

Special Features: Dual extrusion, HEPA air filtration

-

Ease of Use: Remote monitoring, touchscreen interface

The Prusa i3 MK4 is a versatile FDM 3D printer that combines robust build quality with exceptional material compatibility, making it a favorite among professionals. It is perfect for functional automotive components requiring strength and heat resistance, such as brackets or custom housings.

Advantages for Automotive Applications:

- Durable Components: Excels at producing functional, stress-bearing parts like mounts, brackets, and housings.

- Material Flexibility: The ability to print with engineering-grade filaments allows users to create professional-quality parts.

- Reliable and User-Friendly: Known for its consistent output and easy-to-follow documentation.

Limitations:

- Slightly higher cost compared to entry-level printers.

- Open-frame design means it’s less suitable for temperature-sensitive filaments like ABS without additional enclosures.

2. QIDI Q1 Pro

“Best 3D Printers for Automotive Parts“

Key Features

-

Build Volume: 9.65×9.65×9.45 inches

-

Material Compatibility: PLA, ABS, TPU, PETG

-

Precision: ±0.05 mm

-

Special Features: Enclosed chamber, dual platform (magnetic & glass)

-

Ease of Use: Wi-Fi connectivity, user-friendly touchscreen

The QIDI Q1 Pro is a compact yet highly capable 3D printer that excels in producing precise, small-to-medium automotive parts. Its enclosed design and dual-platform system make it a versatile tool for users who value ease of use and material flexibility.

Advantages for Automotive Applications:

- Compact and Efficient: Great for smaller components like clips, custom knobs, or sensor mounts.

- ABS Printing Made Easy: The enclosed chamber minimizes warping, a common issue when printing with ABS.

- Beginner-Friendly: With a touchscreen interface and clear instructions, it’s an excellent choice for users new to 3D printing.

Limitations:

- Limited build volume compared to larger printers.

- Lacks support for advanced engineering-grade materials like Carbon Fiber composites.

3. ANYCUBIC Photon Mono X 6Ks

“Best 3D Printers for Automotive Parts“

Key Features

-

Build Volume: 7.7 x 4.8 x 7.8 inches

-

Material Compatibility: Standard, ABS-like, flexible resin

-

Resolution: 6K LCD for ultra-sharp details

-

Special Features: Stable UV light source, fast printing speeds

-

Ease of Use: Simple resin setup

The ANYCUBIC Photon Mono X 6K is a high-resolution resin printer that stands out for its ability to deliver ultra-fine details, making it perfect for small, intricate automotive parts such as gear models, custom badges, and decorative trims.

Advantages for Automotive Applications:

- Detail-Oriented Production: Ideal for creating components that require a polished, professional look.

- Mold Making: Excellent for producing molds for small components or casting purposes.

- Precision Engineering: Can handle complex designs with tight tolerances, perfect for testing prototypes.

Limitations:

- Limited build volume restricts production to small parts.

- Resin printing involves post-processing (cleaning and curing), which can be time-consuming.

Also Read – Best 3D Printers for Miniatures

Conclusion

From compact printers like the QIDI Q1 Pro to large-scale, professional options such as the QIDI Q1 Pro, and now including the versatile ANYCUBIC Photon Mono X 6Ks, there’s a 3D printer for every automotive need. Assess your project requirements, material needs, and budget to find the perfect fit for your automotive endeavors.

With a degree in Electrical Engineering and years of hands-on experience in the tech industry, passionate to provide readers with insightful reviews. From smartphones and laptops to smart home devices and emerging technologies, he navigates the ever-evolving tech landscape, offering in-depth analyses and honest opinions.